We specialise in turning and milling precision parts from bar stock. We use this technology to manufacture high-performance components that find applications in numerous industries, including automotive, medical, and aerospace. Our extensive production facilities, high-quality equipment, and tools made by renowned brands enable us to fulfil serial and large-scale orders for the most complex products.

While maintaining a regime of impeccable precision, we guarantee an extremely high quality of all our components. This is applicable both in relation to serial and one-piece production. We apply advanced measurement solutions to manufacture products within the tolerance limits specified by our clients.

Our production materials include:

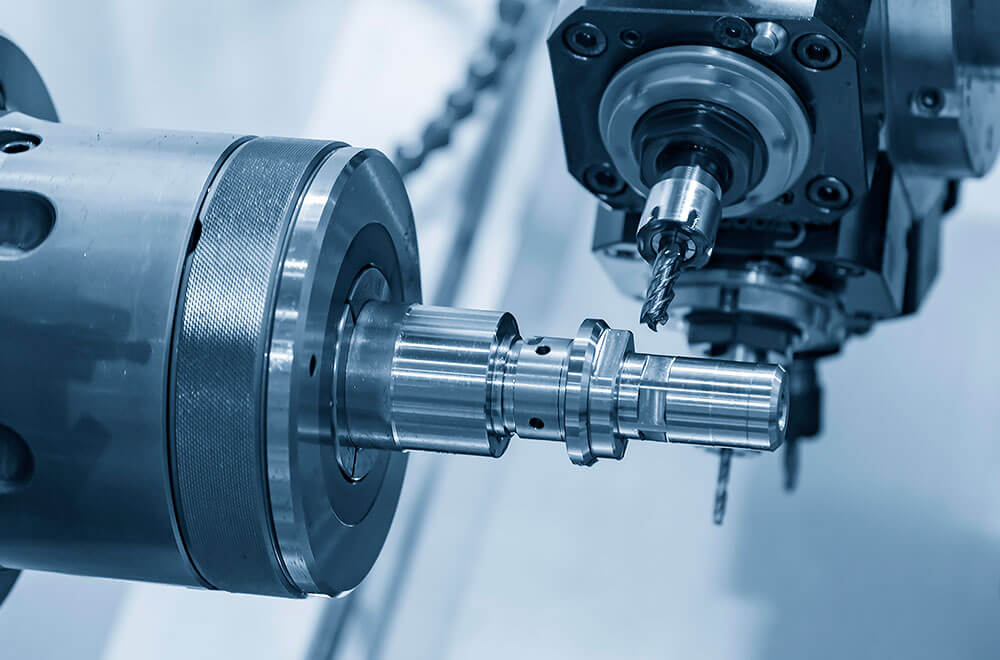

Bar stock CNC turning is a technology that enables the precise fabrication of all types of metal parts.

The input material for machining is bar stock. The entire process is automatic and can achieve a very high degree of accuracy while reducing machining cycle times.

The precision metal components we make are widely used in numerous industries. We can manufacture bushings, fasteners, pins, bolts, adapters, nozzles, and other precision components per custom specifications.

Bar stock CNC milling is performed on turning and milling centres and automatic lathes.

CNC milling is computer controlled, so the whole process is automatic. The workpiece is machined and turned in the same fixture for maximum dimensional and positioning precision even with the smallest geometrical features. The metalworking process is done faster by simultaneous turning and milling.